Feedback

Tengye promotes the whole process management of steel industry projects

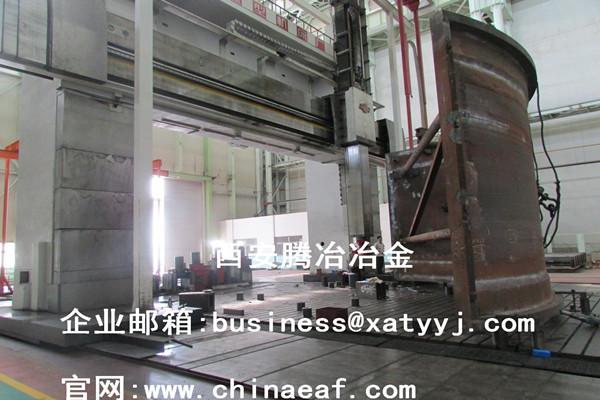

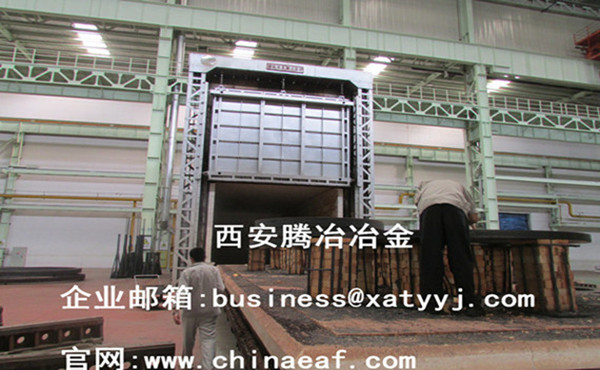

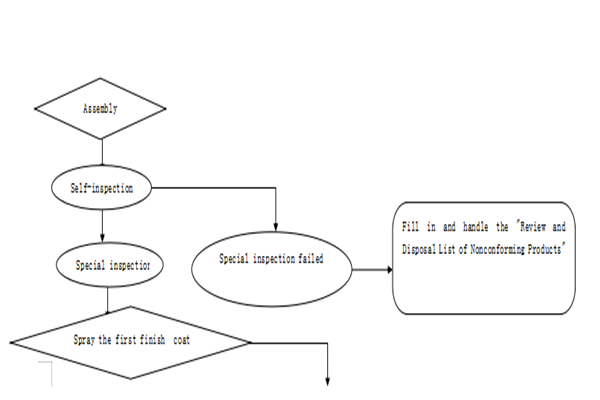

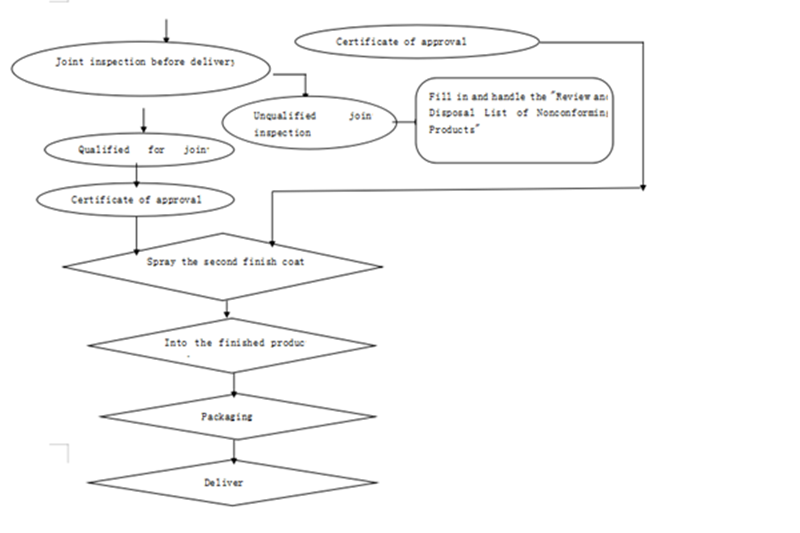

Xi’an Tengye Metallurgical Engineering Co., Ltd. (TYME) implements process documents of project management strictly during project execution; in order to control the quality and progress of outsourcing equipment and outsourcing parts and components effectively, during the implementation process, the company implements to witness and supervise the manufacturing process and inspect and verify important key processes by dispatched supervisors to ensure that the equipment is delivered on time and meet the quality standards. For this purpose, we have made a strict production-supervision process.

Scope of supervision

1. The manufacturing process of a set of mechanical equipment;

2. The blank forming and heat treatment process of important parts or special materials, the machining or assembly process of large or batch or important parts;

3. Integration process of hydraulic and lubrication system;

4. Electrical and drive system manufacturing process;

5. Automation control system integration process.

Xi'an Tengye Metallurgical Engineering Co., Ltd. is a leading provider of EPC project in the metallurgical engineering sector of China, specialized in the metallurgical equipment designing, technology R&D, manufacturing, and installation as well as commissioning.

TYME’s main products are Electric ArcFurnace (EAF), Ladle Refining Furnace (LF), Vacuum Refining Furnace(VD/VOD), Submerged Arc Furnace (SAF), Dust collection system, Continuous casting machine (CCM) and Rolling Mill.

Other products such as auxiliary equipment for CCM, Rolling mill are also available based on customer needs.