Feedback

The Rolling Mill of TYME ESP General Contract Project Successfully Completed the Vertical Installation Inspection

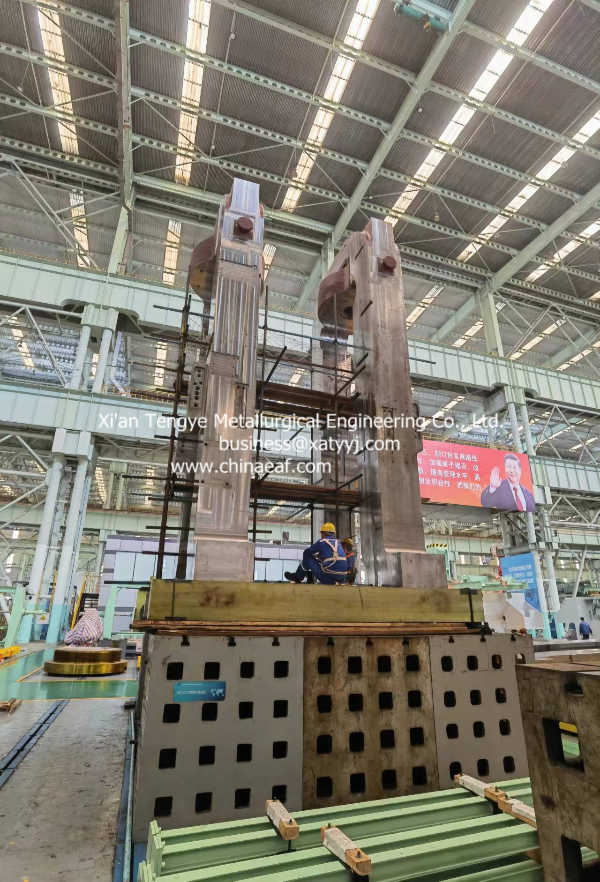

Recently, in the ESP general contracting project undertook by Xi'an Tengye Metallurgical Engineering Company, the main body of the rolling mill frame has been completed. To ensure the product’s service precision on site, and make sure it can be smoothly installed and put into production, Tengye quality inspection team carried out the vertical installation of the rolling mill before delivery.

Facing such a large equipment, weighing more than 120t, with complicated vertical installation method and heavy amount of work, the quality inspection project department of Tengye has researched over and over, formulated an inspection plan, and made a layer-by-layer disclosure, laying a solid foundation for later vertical installation. Through the installation inspection, the Tengye team believes that the rolling mill will be successfully installed and function well during later phases.

Xi'an Tengye Metallurgical Engineering Co., Ltd. (TYME) is a leading provider of EPC projects in China's metallurgical engineering field, specializing in metallurgical equipment design, technology research and development, manufacturing, installation and commissioning since 2011. The company's main products are electric arc furnace, ladle refining furnace, vacuum refining furnace, dust removal system, continuous casting machine, rolling mill, and so on.

As the largest ESP project in the world at present, this project is both a challenge and an opportunity for the Tengye team. Tengye's quality inspection team and on-site personnel are meticulous and strive to make sure that there is no deviation in every link. Only in this way, Tengye’s products can be an international brand and be recognized by more people.