Feedback

An overseas 1422mm hot rolling modification project conveying line completed the assembly dimension inspection

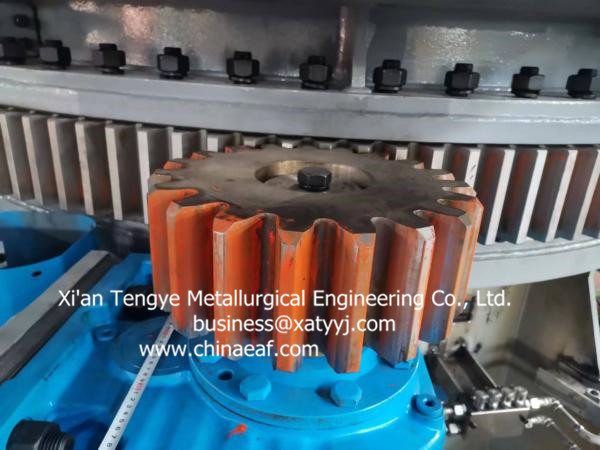

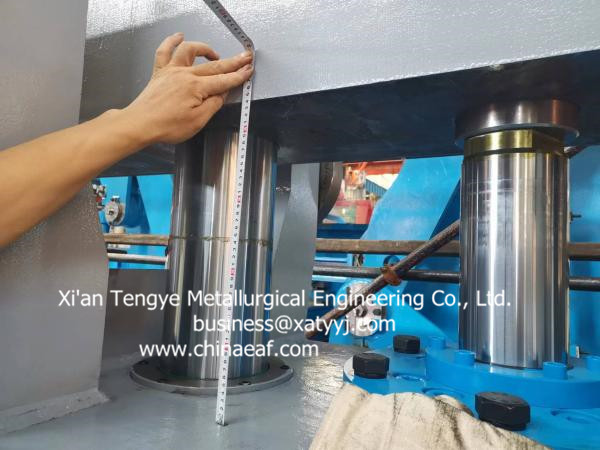

A few days ago, the conveying line of a overseas 1422mm hot rolling modification project undertaken by Xi'an Tengye Metallurgical Engineering Co., Ltd. completed the assembly dimension inspection of the main equipment.

This line mainly involves coil stripping car, coil conveying car, roller table, lifting machine, turntable, traversing vehicle, locking device, intercepting device, etc.

For this project, Tengye adopted a combination method of self-inspection and third-party inspection. Each inspection follows the quality inspection process, the inspectors record the inspection results of the inspected parts one by one, report them to the relevant departments of the company, and submits an inspection report to the owner, as well as photos and videos of the inspection site, etc., to ensure that the owner has the latest inspection information of the contract product.

It is learned that the 1422mm hot rolling modification involves design transformation, procurement and supply of equipment and materials, renovation of old equipment, equipment installation guidance, commissioning (including on-site technical guidance), hot loaded test run, after services, etc.