Feedback

|

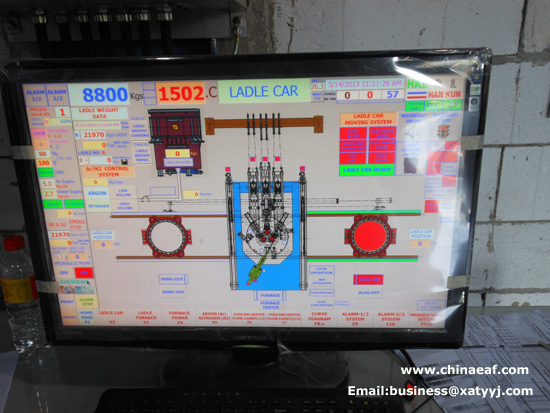

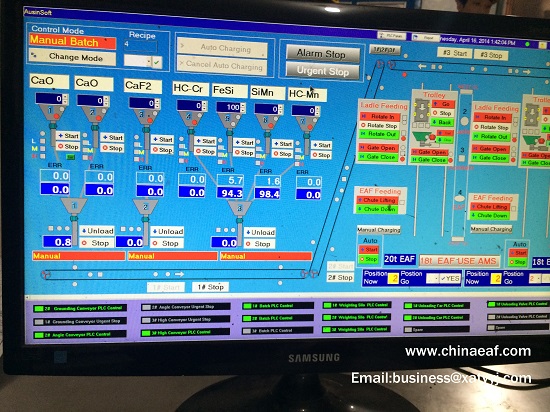

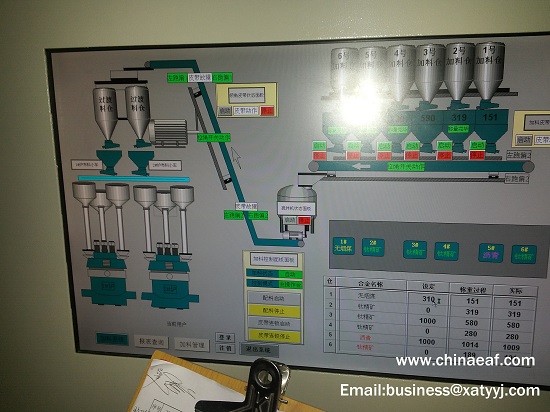

1.The electrode Automatic pressure release function Based processes require, precise voltage discharge electrode,greatly improve the stability, reliability of electricfurnace production,the reductionof electrode fracture rate, to ensure safety, high efficiency, stable operation of electric furnace. 2. Electrode lifting function Based process requires accurate control electrode operation. 3. The function of automatic control feeding Accordingto processrequirements, timing, quantitative automatic adding material to the furnace. The feeding uniformity, stability, to ensure continuous and stable operation of electric furnace, to improve the level of automation. 4. Detection and display of operating parameters Electric furnace operating parameters such as:current,voltage,power factor,temperature, pressure and other parameters in real-time detection and control,and a sound alarm,all parameters, status can be displayed on the color display. 5. Automatic and manual switching function To ensure system reliability.equipped with a set of manual control buttons,manual control can be used under any circumstances. 6. The operation parameters of storage and printing function Instant printing and timing print arbitrary choice,operating parameters can be prolonged storage,access to,easy to manage. 7. The network function With the LAN network, the parametercan be remote monitoring furnace operation, improve the enterprise automation management level.

|

The Ladle-Furnace EAF Charge Mixture SystemElectronic Control Screen Data Monitoring |

|||||||||

|

||||||||||