Feedback

Tengye team paid a return visit to Indonesia project

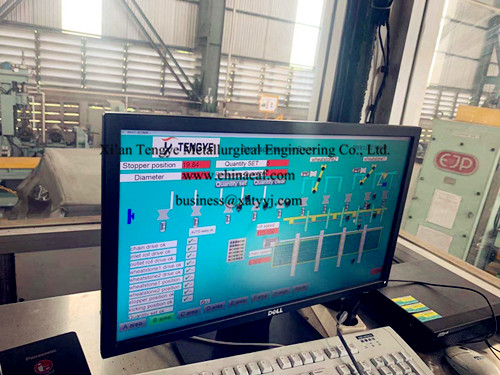

Recently, the Tengye team visited Indonesia and made a special return visit to the contracted bar and wire finishing line equipment project and checked the equipment operation status of the project.

The project is located in Surabaya, Indonesia, and belongs to Mitsubishi Corporation. In this project, the owner values Tengye's excellent equipment quality, perfect project management, high-quality on-site installation and commissioning, fine post-maintenance, and supporting personnel training level and ability, and finally reached cooperation with Tengye to carry out the project. During the implementation of the project, Tengye provided relevant main equipment to the owner, including electric arc furnace (EAF), ladle refining furnace (LF), VOD vacuum refining furnace (VOD/VD), Continuous casting machine (CCM), Rolling mill and Rebar Finishing line.

The bar and wire finishing line equipment project has been in operation for more than two years since its completion. The overall operation is good, the equipment is stable, and there are no major faults and problems during operation. The personnel training conducted by Tengye has a prominent level of business technology, which reflects its good professional quality in operation, management and maintenance equipment. This also reflects Tengye's strength in after-sales service, including in personnel training.

During the return visit, the owner expressed satisfaction with the quality of Tengye's equipment and stated that if there were any new projects, he would continue to contact Tengye directly. This also reflects Tengye's consistent focus on product quality and customer experience, and has won the hearts of owners through high-quality products. Tengye also expressed the hope to further explore potential customers and provide more customers with better products and services.