Feedback

Tengye conducts node inspection on an overseas turnkey project

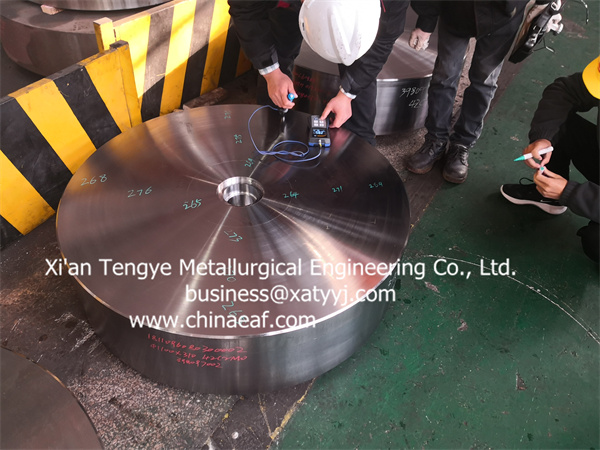

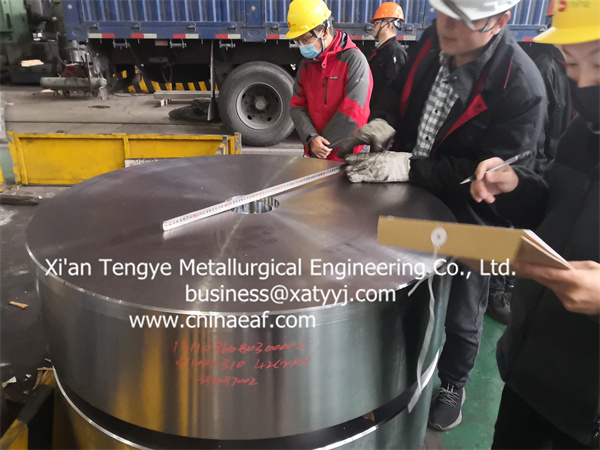

Recently, the Quality Inspection Department of Xi'an Tengye Metallurgical Engineering Co., Ltd. assigned three groups of personnel to different manufacturers to conduct a comprehensive and detailed quality inspection of an international rolling mill turnkey project.

For all EPC projects undertaken, Tengye strictly implements its process control management and quality control management procedures at all stages of the project. The purpose is to implement effective control of the equipment design, manufacturing and service process to ensure that the quality characteristics meet the specified requirements.

During this inspection, Tengye's inspection team conducted node inspection reviews at each manufacturer. From parts to complete machines, they followed the quality inspection process to record the results of inspected parts and make report to related departments. For nonconforming parts found during inspection, they reported to the relevant personnel of the company in time and let the manufacturer provide a solution at the first time to ensure that there is no hidden quality hazard in each link of the project.

Since its establishment, Tengye has always regarded product quality as the foundation of the company. As the saying goes, if you don't accumulate steps, you can't reach thousands of miles. Product quality relies on the controls in every link, and no link is not important.

Tengye has a set of professional project process quality control procedures, in short, there are the following points:

I. Basis for production supervision:

1. Order contracts or technical agreements related to quality.

2. Equipment drawings, manufacturing processes, technical standards, meeting minutes, drawing modification notices and other relevant technical documents.

3. "Outline of Equipment Inspection Before Delivery".

4. "Manufacturing Process Inspection Plan".

5. "Supervision Plan".

II. Supervision content:

Qualification confirmation, document review, on-site witness, record verification, physical inspection and follow-up disposal.

III. Supervision Form:

Two methods are adopted: equipment in-plant supervision & routing inspection of important parts or key processes.

It is this meticulous attitude and super execution ability that make Tengye go further and further in the international project management. While making great strides forward, Tengye people have never forgotten their original aspirations, strictly control the quality, and are committed to providing the best products and services to the owners.