Feedback

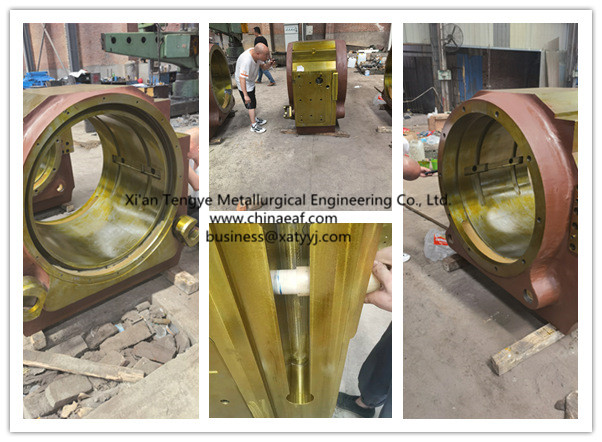

ESP Project Chocks Are Under Production and Inspection

Recently, the backup roll chocks and work roll chocks of Xi'an Tengye ESP project are being produced and inspected smoothly. Up to now, the heat treatment process of a total of 36 pieces of backup roll chocks are all completed. 18 pieces are undergoing finishing and grinding process, and 18 pieces have successively entered the roughing and semi-finishing process. Inspection of chemical composition, mechanical properties, dimensional inspection in rough machining process, and UT flaw detection inspection were implemented on all 36 pieces of backup roll chocks, and the inspection results are all positive. There are 36 work roll chocks in total, all of which have completed the casting process and have successively entered the sand cleaning and heat treatment process. Among them, 20 pieces have been transferred to the roughing process and the sampling process after the finishing process has been completed. Later on, the batch of backup roll chocks and work roll chocks will enter the finishing stage.

For all the production projects undertaken, Tengye strictly controls its engineering process and quality procedures at all stages of the project. The purpose is to implement effective control of equipment design, manufacturing and service processes to ensure that its performance meet the specified requirements.

For this project, Tengye adopts a combination method of self-inspection and third-party inspection. Each component needs to undergo a series of inspection procedures such as chemical composition identification, mechanical performance test, UT flaw detection test, MT flaw detection test, finishing dimension review, etc..

Each inspection are done by following the quality inspection process, recording the inspection results of the inspected parts one by one, reporting them to the relevant departments of the company, and submitting inspection reports, photos and videos of the inspection site to the owner, etc., to ensure that the owner has the latest inspection information of the contract products.